In this guide, you will find all information you are looking for about sheet metal blanking. Whether you want to learn about the actual process, benefits, failure mechanism or compare it with other processes – you will find all information right here.

What Is Sheet Metal Blanking?

In sheet metal blanking, you will use punch and die system to extract suitable part from a large sheet metal. The extracted piece is the blank and one machine operation can blank multiple sheets simultaneously.

Sheet Metal Blanking Process

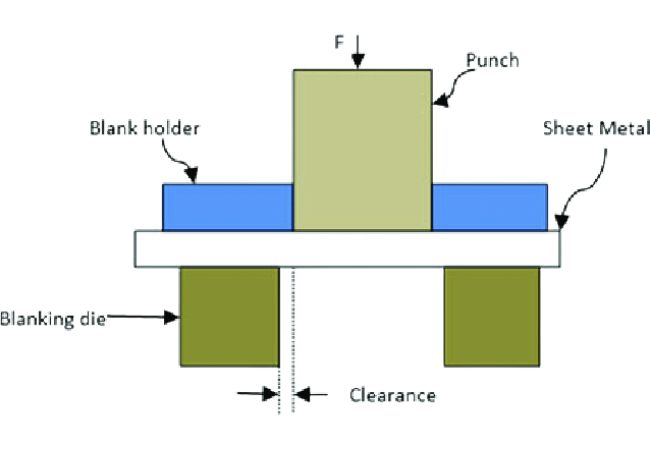

The sheet metal blanking process involves a press, punch and die system working on a metal sheet. It takes the following form:

i. The metal sheet is positioned over the die containing the desired geometry cutout within the blanking press. The punch above the sheet is also in the desired part shape.

ii. The press mechanically or hydraulically exerts a vertical force on the punch which acts on the sheets at great speed.

iii. The punch and die tooling have a clearance fit allowing the punch to shear the metal sheet in the desired shape.

iv. Shearing happens upon impact extracting the blank which falls into the die cavity.

Difference between Sheet Metal Blanking and Punching

The execution process in sheet metal punching and blanking is virtually the same. However, there lies an inherent difference in the end product.

In sheet metal blanking, the desired part is the section which you punch out from a metal sheet in the die. However, in sheet metal punching, you discard the part extracted through the punching process. The remaining part is usually the useful section.

Sheet Metal Blanking Methods

Even though the blanking process of sheet metals seems straightforward, there are a few variations resulting in the following methods:

1. Continuous Strip Blanking

Involves the continuous feeding of sheets of metal into the banking press allowing accurate reproductions. Production of components such as medals, coins and bottle tops utilizes this method.

2. Fine Blanking

Lacks a fracture zone upon shearing thanks to compression of the whole sheet before blank extraction by a top and bottom punch pairing. Fine blanking achieves tight tolerances and reduces burr occurrence resulting in smoother edges reducing need for secondary operations such as deburring.

3. Compound Die Stamping

Finds use in the production of complex parts fashioned from steel strips through feeding a fast output stamping machine. The simplicity, fast and accurate nature of the compound die stamping method allows use in large productions of steel parts.

4. Cutoff

Combines the metalworking processes of cutting and blanking resulting in customized planks in long flat shapes.

5. Square Sheared Blanking

Produces quadrilateral blanks with contours by employing unique clamping tools. It is especially useful when making square shaped components such as box panels.

6. Progressive Die Stamping

Employs thin sheet metals in coiled strips with the machine executing a stamping, trimming and bending operation for parts. The parts leave in form of conjoined strips separated in a later operation into identical and individual parts.

Sheet Metal Blanking Machines

When blanking sheet metals, you require vertical force application to push the punch through the die. The vertical force stems from pressing machines with the following most common:

Hydraulic Press

Hydraulic press machines in sheet metal blanking employ hydraulic pressure stemming from a reliable fluid through a pump and valve system. While they can sustain extended blanking operations, they are relatively slow and inadequate for large production volumes.

Mechanical Press

Employ motors as the driving force of the blanking operation by transforming rotational force into a vertical force. The fast execution of mechanical press machines makes them ideal for large production operations.

Failure Mechanism in Sheet Metal Blanking Punches and Dies

Blanking punches and die typically employ tool steel or carbide in their construction for their strength and durability. However, failure of the blanking tool system is not inconceivable as follows:

Abrasive Wear

Evidence of abrasion is typically along the sliding contacts upon interaction of the tool and metal sheet. Tooling requires high hardness levels such as carbides to overcome abrasive wear.

Adhesive Wear and Galling

Adhesive wear and galling result from stresses due to compression, friction induced by contact movements and temperature rise. Having a tooling with high coefficient of friction, hardness and toughness is essential in preventing adhesive wear and galling.

Breakage and Chipping

When using material with low toughness, cracks can manifest and end in chipping or breaking of the tool. Having a tool material with homogenous and fine structure offers reliable strength show in impact and fatigue.

Plastic Deformation

Sometimes the blanking force on the punch exerts a stress that overcomes the tools steel’s yield strength resulting in deformation. When blanking tougher metal sheets, employing a harder tooling such as carbide is essential.

Sheets Metal Materials When Blanking

The application of the blanked part influences the sheet metal material in blanking. Each material offers different properties such as corrosion resistance, toughness and conductivity.

Materials you can employ in blanking include:

1. Stainless Steel

Contains chromium which increases this material’s resistance to corrosion and thus lifespan allowing use in damp and high humidity environments. Blanked stainless steel components find use in making medical products, food packaging, kitchenware and even construction.

2. Aluminum

Aluminum metal sheets are malleable, flexible, low cost, light, durable, highly recyclable and readily available. Sheet metal blanking aluminum allows production of parts and components used in aerospace, packaging, automotive, energy and household equipment.

3. Copper

Copper sheets offer you blanked parts with impressive resistance to corrosion and thermal and electrical conductivity.

4. Carbon Steel

The carbon content influences the hardness of carbon steel resulting in low, medium and high carbon classification. Blanked components from carbon steel sheets finds automotive and industrial application thanks to carbon steel’s strength and versatility.

5. Iron

Iron metal sheets offer you incredible mechanical properties such as toughness useful in making blanked parts for machines.

6. Galvanized Steel

Galvanized steel overlays steel with a uniform zinc layer to offer increased protection from corrosion. Blanked parts extracted from galvanized steel are useful in manufacturing automotive, aerospace, and appliances.

Deburring Methods in Sheet Metal Blanking

Sheet metal blanking results in blanks with imperfections of rough edges called burrs which affect part quality, functionality and are unsafe. Deburring enables you to remove these imperfections to ensure product quality, functionality and safety in use.

Common deburring methods include:

Barrel Tumbling

Involves components crushing against each other in a high-speed tumbling barrel thereby removing burrs and other surface imperfections.

Electromechanical Deburring

In this deburring process, removal of burrs involves dissolution in an electrically induced solution of salts or glycol. This process is appropriate for small blanked components with complex geometries, but its duration makes it suitable for small productions only.

Manual Deburring

Entails removal of burrs by hand by utilizing tools such as files and sandpaper. Deburring manually is a cost effective process that has impressive results when done skillfully. However, undertaking manual deburring is time intensive and thus unsuitable where you have large component volumes.

Thermal Deburring

Employs combustion in a sealed furnace to dissolve or burn off the burrs via explosion. Thermal deburring simultaneously eliminates burrs on multiple component surfaces finding use for high precision component production.

Nevertheless, this process set up is costly and is not highly efficient as it can fail to clear some burrs. Additionally, the conditions can result in part deformation and rust development on component surfaces.

Vibratory Finishing

Especially regarding blanks from soft metal sheets like aluminum, this method is highly efficient and less aggressive. Involves subjecting the components to abrasive media in a vibrating vessel that causes burr removal by rubbing.

Advantages of Blanking Sheet Metals

Blanking sheet metals is a simple and fast process for producing identical components of a desired geometry for use in different applications. Some outstanding features of sheet metal blanking are thus described:

i. Configuration of equipment in blanking and metal sheet feeding process is straight forward given the desired component geometry allowing quick production.

ii. Conduction of extended production lines without interruption such as tooling changes is possible allowing fast lead times.

iii. Possible to undertake blanking of components with different geometries with tight tolerance by employing different tooling’s in a single machine.

iv. Reduces material waste by allowing reuse/recycling of stock since the blanking process does not alter the material’s properties.

Limitations in Sheet Metal Blanking

While there are several pros in employing sheet metal blanking, the blanking process has the following limitations:

- Most blanking methods of sheet metals results in components with surface imperfections called burrs requiring secondary finishing. This increases the production cost and time

- While employing finer techniques like fine blanking can limit burring, this comes at a high investment cost for acquiring such equipment.

Applications of Steel Metal Blanking

Blanking is an essential metal working process in the production of highly identical parts and components. Some of the areas these components find use include:

- Manufacture of aircraft parts

- Automobile production especially engine, transmission and body parts

- Pat fabrication for household appliances such as white goods

Conclusion

Sheet metal blanking plays an integral role in modern sheet metal fabrication process. However, you can only get high quality parts and components if you follow the right process.

For all your sheet metal blanking needs, contact us now.

mmgwveeglrxhzxdwsyegrdrysjtsdq

lqkplskdpeewwdmergynwumjtfrukz

Pak555game… hmmm, never heard of this. Well, why not give them a try. More competition, more potential! Check them out: pak555game

Yo, 1cassinobet is pretty decent! They got a good selection of games and the site’s easy to navigate. I’ve had some good luck there, so check out 1cassinobet

Yo, signing up for W88 can be a pain sometimes, but dangkyw88 makes it super easy. Smooth process, highly recommend giving it a shot if you’re looking to join them. Go sign up at dangkyw88!

https://www.befg777link.com I am thanksful for this post!

playpal77 https://www.playpal77sy.org

ph789 login https://www.ph789-login.com

bk8casino https://www.bk8casinovs.com

gkbet https://www.gkbeth.org

pin77 casino https://www.pin77-ol.com

taya777login https://www.wtaya777login.com

98jili https://www.98jilig.com

vipjili https://www.vipjiliji.com

jilivip https://www.jilivipu.net

slotphlogin https://www.exslotphlogin.net

okebet168 https://www.okebet168u.org

fg777link https://www.befg777link.com

phtaya 63 https://www.phtaya-63.org

phl789 https://www.nphl789.net

pin77 app https://www.pin77.tech

tayabet https://www.yetayabet.net

jililuck 22 https://www.jililuck-22.com

fb777 slot https://www.fb7777-slot.com

phtaya01 https://www.phtaya01.org

phtaya06 https://www.phtaya06y.com

nustaronline https://www.umnustaronline.org

okebet4 https://www.okebet4u.com

tg77com https://www.tg77com.org

tayawin https://www.tayawinch.net

a45com https://www.a45com.org

okbet15 https://www.okbet15.org

pesomaxfun https://www.elpesomaxfun.com

fb777login https://www.fb777loginv.org

okebet3 https://www.okebet3u.org

tongits go https://www.yatongits-go.net

jiliokcc https://www.jiliokccw.com

phtaya1 https://www.phtaya1.org

2jili https://www.2jili.org

mwplay88fun https://www.mwplay88fun.org

jl16login https://www.adjl16login.net

phtaya10 https://www.phtaya10y.com

taya333 https://www.taya333.org

777phl casino https://www.777phl.org

peso99 https://www.repeso99.net

bet777app https://www.bet777appv.org

pagcor https://www.ngpagcor.net

9apisologin https://www.it9apisologin.com

balato88 https://www.balato88u.com

99boncasino https://www.99boncasino.net

jl10 casino https://www.jl10-casino.net

91phcom https://www.91phcom.net

nustar online https://www.etnustar-online.com

77jili https://www.77jilig.net

phtaya11 https://www.phtaya11y.com

philucky https://www.usphilucky.org

93jili https://www.la93jili.net

B955gamedownload, could be a good source for games. Double-check that the downloads are safe before installing anything yeah? Here’s the link: b955gamedownload

Been hearing some buzz about gorillabet.info. Gave it a look and the odds seem competitive. Their interface is pretty clean too. Worth a punt if you’re into sports betting! Check it out here: gorillabet

Downloaded the e7777gameapk and it’s pretty slick! Install was easy, and the games are surprisingly fun. A decent way to kill some time, I reckon. Check it downloads here: e7777gameapk

jili777 https://www.jili777g.org

mdrplay https://www.remdrplay.org