Costom Metal Enclosure Manufacturer

OEM and ODE services, “customized” metal housings for your application, ensure perfect fit and protection.

Costom Metal Enclosure

The metal shell is an external protective shell made of metal materials, which has the functions of waterproof, dustproof and earthquake resistance. Mainly through laser cutting, rapid prototyping, bending, punching, welding, assembly and surface treatment and other processes. We have a wide range of raw materials for you to choose from: sheet metal, carbon steel, stainless steel, cold rolled steel and aluminum. Our shells are widely used in aerospace, electronic appliances, communications, construction, automotive industry, medical equipment and other fields.

Futai is a leading global manufacturer of metal casings. We provide one-stop sheet metal shell processing and optimal production solutions according to your needs. We believe that our team will be able to provide you with quality products, services and prices. Whether you need a one-off custom metal case or continuous production, Futai can help you with all your case manufacturing needs.

You only need to provide the metal shell box size design drawing and product customization needs to get a free quote (futai@metalsheetprocessing.com), please feel free to contact us.

Futai Metal Shell Processing Technology

In the production of metal shell, we use the most advanced mechanical equipment, such as laser cutting machine, CNC bending machine, automatic welding machine, inspection machine and other equipment. There are also many production processes for metal casings, such as:

√ Laser cutting

√ bend

√ punching

√ weld

√ assemble

√ Numerical control milling

√ Surface treatment

√ Rapid prototyping

Sheet Metal Fabrication Techniques

There are a plethora of sheet metal box fabrication techniques available. But our expertise in the fabrication procedures is listed below. Which enables us to produce a wide range of sheet metal box projects.

- Welding – unites many pieces of metal with a concentrated application of heat and pressure.

- Deburring – used to clean the sheet metal’s edges, remove burrs and conceal mental flaws.

- Punching – create precise holes and forms

- Bending & Forming – both use presses to mold a sheet of metal into a certain shape.

- Hardware Insertion – forming a nut, stud, standoff, or other special items into a sheet metal part using force.

Futai Metal Housing Material

Custom metal shell materials are recyclable, have a low impact on the environment, promote resource reuse and contribute to sustainable development. For the best quality metal materials available:

Aluminum: It is a lightweight, strong and corrosion-resistant metal, of which 5052 and 6061 aluminum are often used as the main materials for custom housings.

Stainless steel: High tensile strength, can provide higher corrosion resistance, ideal for custom shell designs with high demand.

Steel: is the most ideal choice for manufacturing mechanical shell, low cost, easy to bend without deformation.

The above are several materials commonly used in metal shells, and different materials have different advantages and disadvantages in different occasions. In the selection of materials need to weigh various factors according to the actual situation, choose the most suitable material.

Why Choose Futai to Customize Your Enclosure

Futai offers a full range of metal casing manufacturing services and all our manufacturing takes place in-house, giving us full control over production and ensuring that your custom casing is manufactured to the highest quality standards and to your exact specifications. For decades, we have been praised as a “reliable” supplier by customers from different countries. If you would like to start your custom metal shell project, please contact our team today.

Costom Metal Enclosure Products

Futai offers a full range of metal casing manufacturing capabilities, from initial product design to small and high volume production, to provide customers with high quality metal casing products.

Custom aluminium profile housings

Extruded aluminum shell light weight and strong plasticity, corrosion resistance, good thermal conductivity for harsh industrial environments, for electronic products, electrical equipment, LED lights and so on.

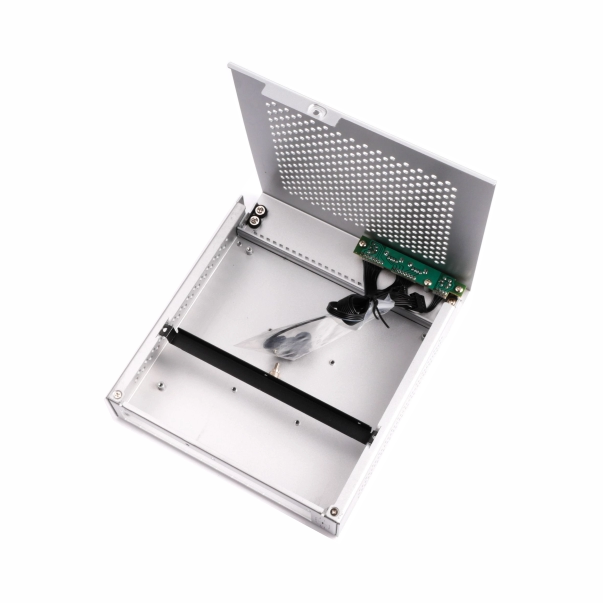

Custom Communication Housings

The metal telecommunication shell protects the equipment more effectively, enhances the signal reception of the telecommunication equipment, and improves the communication quality. Used in automobiles, home appliances, electronic equipment, industrial equipment, optical and instrument equipment, etc.

Custom Junction Box Electrical Enclosures

Metal electrical shell with explosion-proof function, strong adaptability, can effectively protect the internal components and extend the life, used in industry, communication, medical, household appliances and so on.

Custom Stainless Steel Electrical Enclosures

Stainless steel housing with high strength and sealing properties, waterproof, dust resistant. Used in automobile manufacturing, machinery, construction, chemical and food industry, kitchen utensils and other fields.

Custom Steel Housings

Customized shells are designed and manufactured according to specific needs to meet the needs of different applications, and can be made of various mechanical equipment Enclosure.

Small metal electrical enclosures

Metal enclosures provide equipment performance and safety while reducing maintenance costs. Used in energy, electricity, machinery, electronic appliances and so on.

45 metal shell products have been found for you, contact the Futai manufacturer to discuss more about custom metal shell products.

Enclosure Manufacturer, OEM Supplier

We are Metal Enclosure manufacturer, providing custom Metal Enclosure for OEM, please contact the Futai manufacturer

Advantages of Sheet Metal Classis Box Fabrication

1, durable: the metal shell has excellent durability, if proper maintenance can be used for a long time, suitable for long-term needs of projects.

2, versatility: the plasticity and adaptability of the metal shell make it widely suitable for projects in various industries to meet various needs.

3, easy maintenance: metal shell is not easy to rust, corrosion resistance and fire resistance, relatively simple maintenance.

Resilience

The sheet steel box is sturdy and long-lasting. It can frequently tolerate more pressure and heat. Furthermore, steel materials are all pressure, corrosion, and wear-and-tear resistant.

Ductility

Sheet metal is bendable. It may be twisted into a variety of shapes with the correct tools. In contrast, maintaining its strength and structural integrity. It is also capable of being squeezed.

Stability

Metal is one of the most environmentally friendly materials available. Sheet metal box fabrication is a considerably more eco-friendly and long-term solution. Plus, it’s strong and rigid.

Economical

Sheet metal is a more cost-effective option for tooling expenses. Its strength and longevity will serve for a long time. No need to replace or do daily maintenance.

Sheet Metal Box Fabrication for Different Industries

Electronics

Sheet metal box importance in the electronic industry is beyond measure. They are providing several advantages including emission reductions, electrical conductivity, and so on. These boxes are resistant to harsh industrial environments.

Telecom

Futai specializes in sheet metal box fabrication for communication systems. These cabinets have great features, such as being water-resistant, fireproof, NEMA/UL-tested, and mountable on a wall, tower, or pole. Other models are free-standing.

Aerospace

Boxes for aerospace applications come with a range of material selections. We treat titanium, aluminum, carbon steel, or stainless steel. The dimensions of the pieces are precise and long-lasting. Designed to meet the industry’s stringent requirements.

Energy

Fabricated metal boxes can be utilized to build energy production systems. They are lowering production costs while improving quality and consistency. Futai uses copper, steel, and other materials to build containers for the social energy industry.

Automotive

Futai produces high-quality metal boxes that can withstand the rigors of the semiconductor industry. These enclosures can be used to shield electronics from wear and tear in automobiles. Futai can make large production of boxes for your business.

One-Stop Costom Metal Enclosure Services

10+ Years of Experience. High Precision and OEM Design. Professional R&D Team. Competitive Price.

Related Product