Sheet Metal Fabrication Services

ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified.

Sheet Metal Fabrication Services for Custom Parts

Choose Futai for comprehensive online sheet metal fabrication services. With over 40 sets of advanced machines—including laser cutters, bending machines, and welders—our China-based network handles everything from low-volume prototypes to high-volume production. Our domestic sheet metal fabricators and a team of knowledgeable engineers ensure that each sheet metal component is manufactured to exact specifications and quality standards.

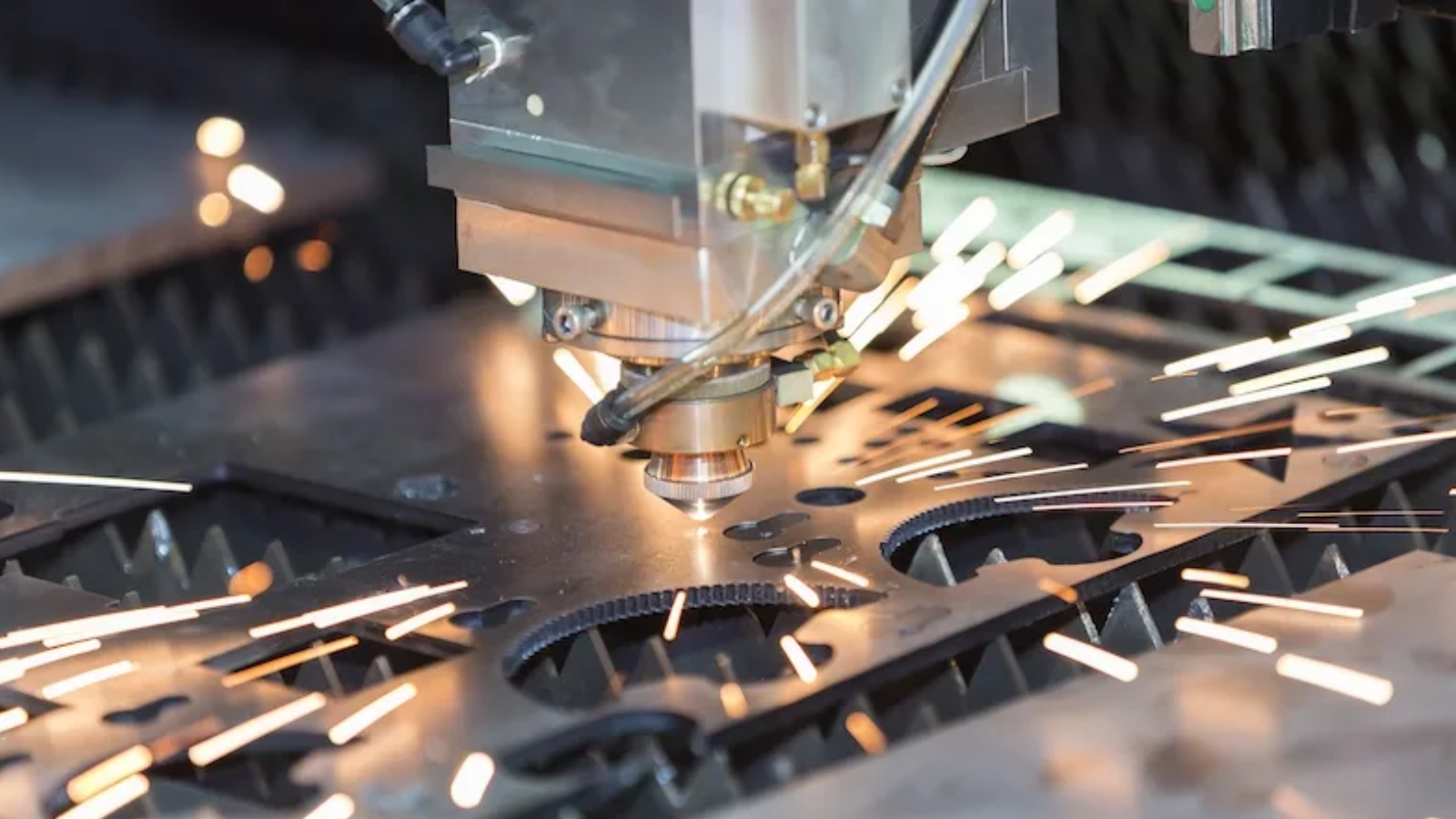

Laser Cutting

Laser cutting is precise and efficient, ideal for complex, high-quality designs with minimal waste. It quickly cuts various metals, delivering clean, burr-free edges.

- Clean, precise cuts.

- Fast, boosts productivity.

- Cuts diverse materials.

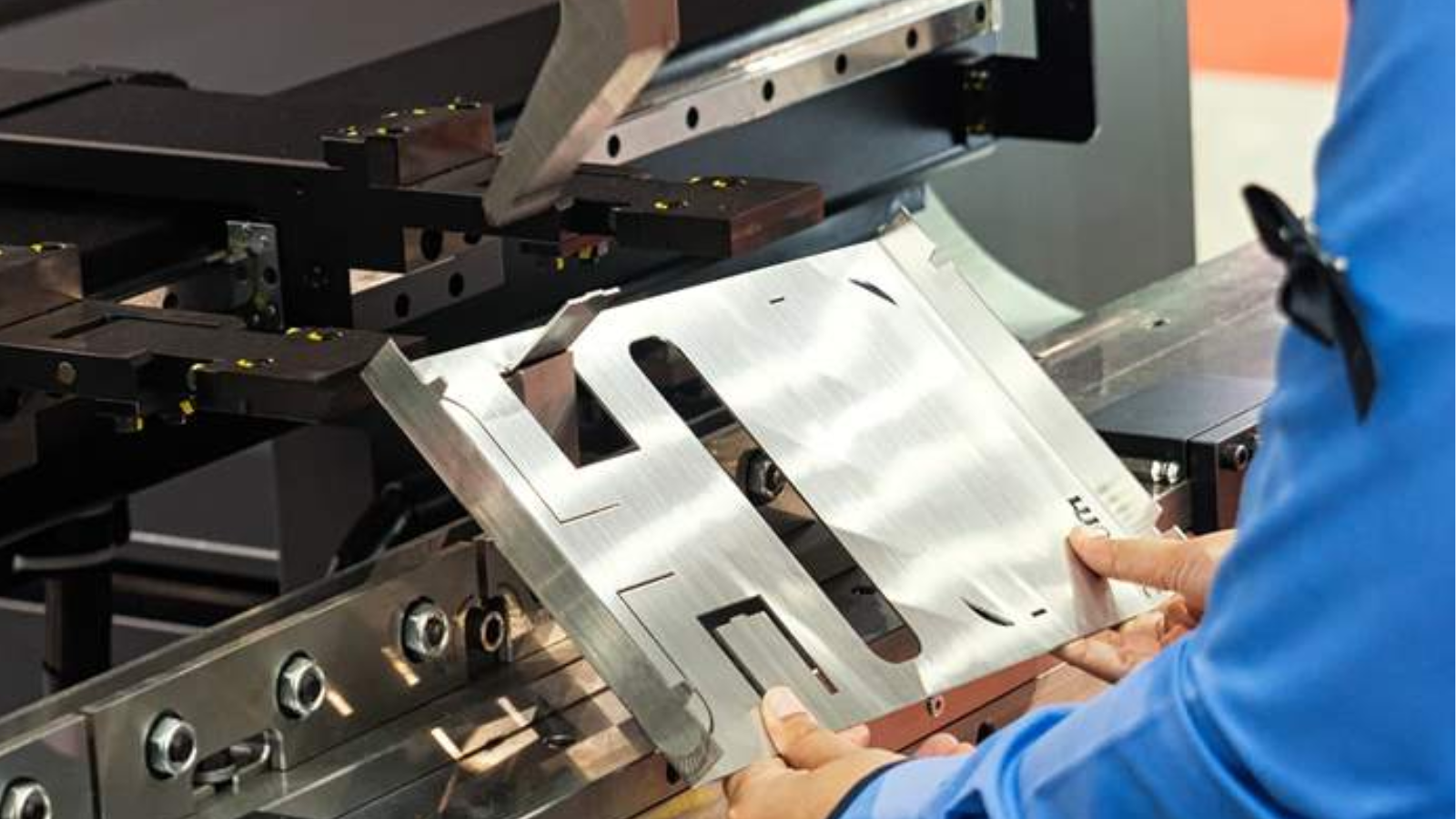

Bending

Bending shapes sheet metal along straight lines using press brakes for accurate angles and consistent dimensions, essential for aesthetics and functionality.

- Achieves accurate angles consistently.

- Quick setup, fast execution.

- Adapts to various materials.

Welding

Welding is a fundamental metal fabrication process used to join metal pieces securely. It involves melting the base metal and a filler material to form a strong joint.

- Creates strong, durable joints.

- Quick, save material costs.

- Suitable for various materials.

Punching

Punching is a cost-effective method for creating holes and intricate patterns in sheet metal. This process, ideal for high-volume production, ensures uniform precision.

- Reduces material and labor costs.

- Uniform, accurate features produced.

- Suitable for large-scale production.

Riveting

Riveting is a reliable fastening technique that joins metal parts without welding. It involves inserting and deforming rivets to assemble complex structures where welding is impractical.

- Durable, reliable connections.

- Avoids thermal distortion.

- Avoids thermal distortion.

Stamping

Stamping presses metal into dies to shape specific forms efficiently. It mass-produces uniform parts and is widely used in automotive industries for complex geometries.

- Rapid, large-scale production.

- Uniform parts every time.

- Manages intricate shapes easily.

Futai Sheet Metal Solutions

PROTOTYPING

Rapid Prototyping

Our rapid prototyping services provide quick turn sheet metal parts that help you validate designs and perform functional testing faster than ever before. It is perfect for making adjustments and achieving the best outcomes for your final product. Benefit from a fast 3-day lead time and economical per-unit costs.

PRODUCTION

Low and High-Volume Production

Adapt swiftly to market fluctuations with our versatile sheet metal production services. We excel in handling custom orders, offering seamless scalability and just-in-time delivery. Benefit from significant reductions in per-unit costs as production volumes increase.

How Does Futai Sheet Metal Fabrication Work

Futai’s expansive network of sheet metal machine shops across China ensures we have the capacity to handle projects of any size, from intricate prototypes to comprehensive assemblies. We start by meticulously converting your CAD designs into precise machine code. Our skilled fabricators then take over, expertly cutting, bending, and shaping the metal to meet your exact specifications. This process leverages advanced fabrication techniques such as welding, riveting, and fastening, all while adhering to rigorous quality standards.

Our facilities are equipped to offer a wide range of finishing options, allowing each piece to achieve not just functional precision but also aesthetic excellence. Whether your need is for a single, custom piece or a large-scale production run, our network is designed to deliver top-quality products efficiently and reliably, ensuring that every project aligns perfectly with your requirements.

700+

Sets of Machine

120+

Countries Shipped

20,000+

Customers Served

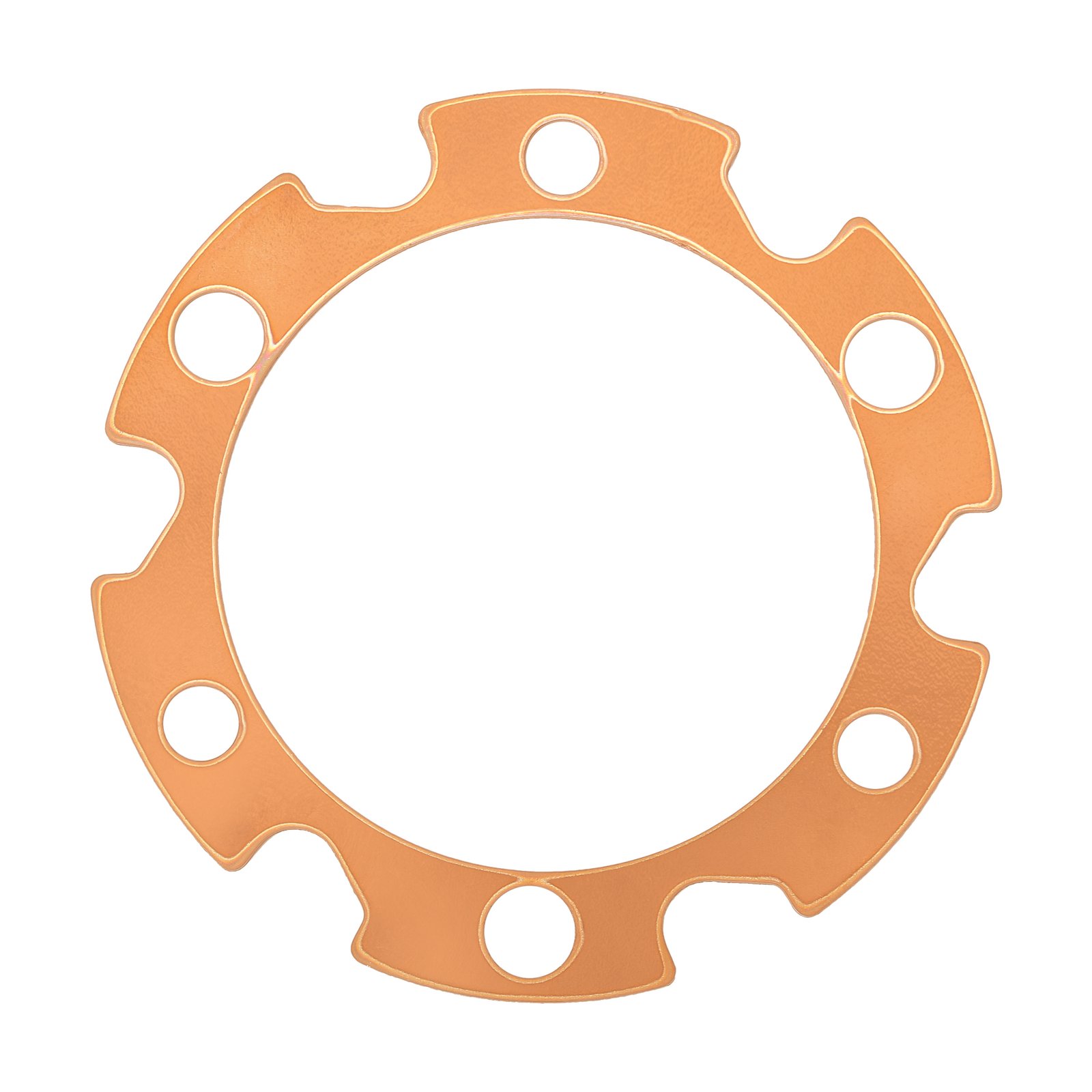

Metal Bending Materials

Choose from a wide range of sheet metal materials including aluminum, stainless steel, and brass. Each material is chosen for its unique properties, allowing us to recommend the best match for your project’s specific needs and applications.

|

Lightweight and corrosion-resistant, aluminum is ideal for applications requiring high strength-to-weight ratios. It’s easily machinable and excellent for aerospace and automotive parts. Alloys Aluminum 5052 Aluminum 5083 Aluminum 6061 (It can be cut with laser cutter but not bender.) |

|

Known for its acoustic properties, brass is highly malleable and exhibits a gold-like appearance. It is often used in decorative applications, gears, and valves. Alloys Brass C28000 Brass C36000 Note: Sheet metal process can not process more than 5MM thickness of brass. |

| Copper stands out for its electrical and thermal conductivity. It’s highly ductile, making it a top choice for electrical components, roofing, and plumbing. Alloys Copper C101(T2) Copper C103(T1) Copper C103(TU2) Copper C110(TU0) Note: Sheet metal process can not process more than 5MM thickness of copper. |

|

Extremely durable and strong, steel is a staple in construction and heavy industries. It can be alloyed with various elements to enhance its properties, such as hardness and resistance to corrosion.

Alloys

SPCC

Galvanized Steel (SGCC / SECC)

Q235

Steel 1020 |

|

Stainless steel is renowned for its corrosion resistance. It is strong, easily cleaned, and maintains an attractive finish, making it suitable for medical, food processing, and marine applications.

Alloys Stainless Steel SUS 304 |

Surface Finishing Options for Metal Sheets

Enhance the durability and aesthetic of your custom metal parts with our variety of surface finishing options. For finishes not listed on our quote page, simply select “Other” and specify your requirements for a customized solution..

As Machined

As machined finish leaves thesurface straight from the CNCmachine, providing a cost-effective option with toolmarks.

Anodizing

Anodizing increases corrosion resistance and wearproperties, while allowing forcolor dyeing, ideal for aluminumparts.

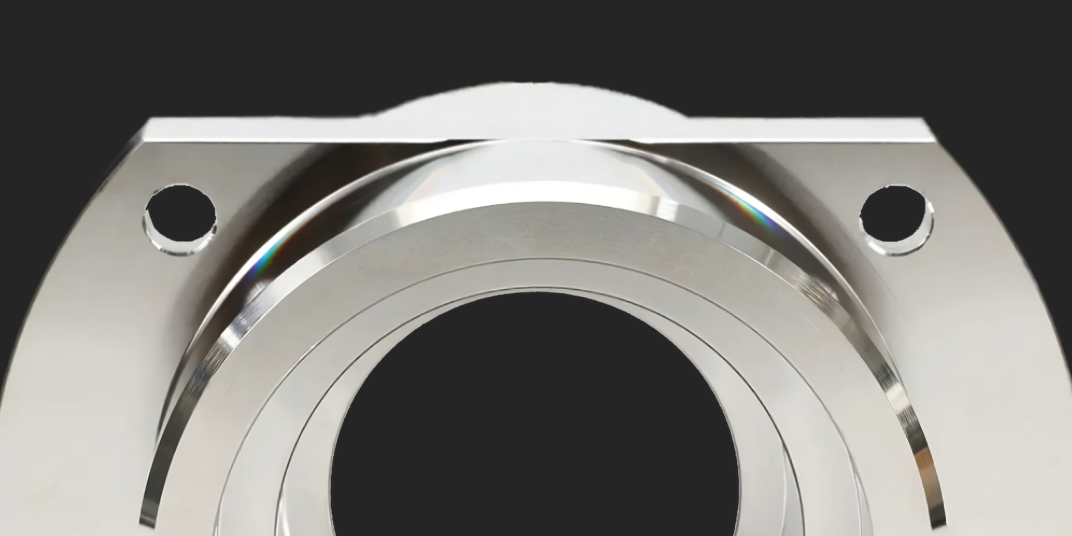

Polishing

Polishing achieves a high glossfinish, reducing surfaceroughness and enhancing theaesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurizedsand or other media to cleanand texture the surface.creating a uniform,matte finish.

Tumbling

Tumbling smooths and polishes small parts by friction andabrasion in a barrel, offering aconsistent but slightly texturedfinish.

Electropolish

Electropolish is a chemicalprocess that smooths andbrightens surfaces whileimproving corrosion resistance.

Alodine

Alodine coating providescorrosion protection andimproves paint adhesion,mainly used on aluminumsurfaces.

Heat Treatment

Heat treatment alters themechanical properties of metalto increase its hardness,strength, or ductility.

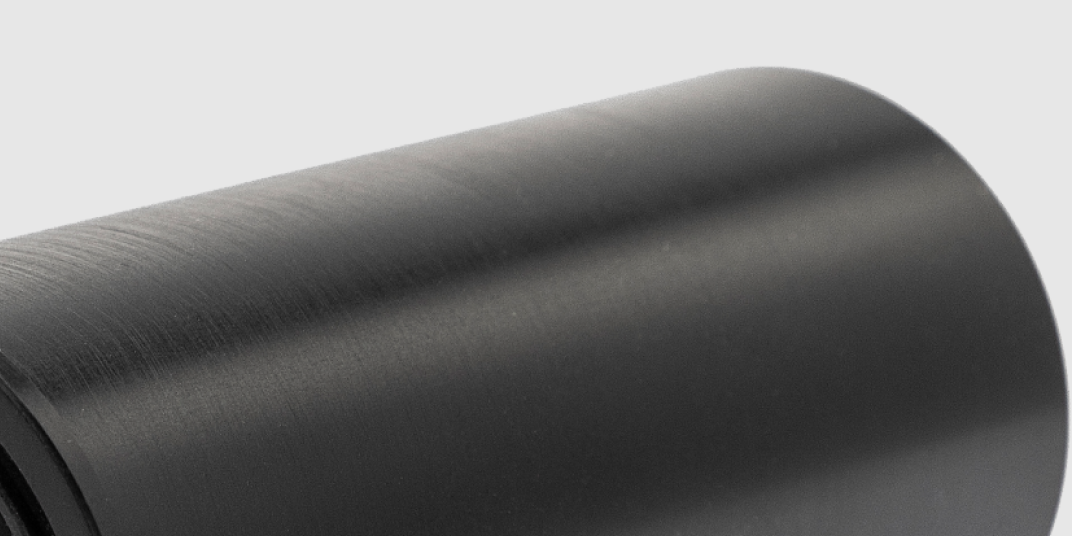

Brushed Finish

A brushed finish creates aunidirectional satin texture,reducing the visibility of marksand scratches on the surface.

Powder Coating

Powder coating applies a thick,wear-resistant layer withexcellent color and textureoptions, suitable for a variety ofsurfaces.

Electroplating

Electroplating bonds a thinmetal layer onto parts,improving wear resistance,corrosion resistance,andsurface conductivity.

Black Oxidize

Black oxidize is a conversioncoating for ferrous metals thatimproves corrosion resistanceand minimizes light reflection.

Sheet Metal Fabrication Capabilities at Futai

Description

Metal Bending Forces

Up to 1000 tons

Metal Bending Forces

Up to 1000 tons

Sheet Metal Fabrication for Various Industries

Our precision sheet metal fabrication services cater to a diverse range of industries, from automotive to aerospace, ensuring high-quality, custom parts for any application.

Aerospace

Automotive

Automation

Medical Devices

Robotics

Consumer Products

Why Choose Futai

Parts

We ensure your parts are flawless with ISO-certified quality, comprehensive reports, and rigorous inspections for dimensional accuracy and functionality, solving critical reliability concerns.

Lead Time

We guarantee lead times as fast as 3 days, leveraging infinite capacity and flexible shipping options. Accelerate your sheet metal projects, ensuring timely delivery and a competitive edge.

Support

Overcome complex design challenges with RapidDirect’s engineering experts. Our expertise ensures precise, innovative solutions, reducing your workload and elevating product quality.

Advantages of Sheet Metal Fabrication

Sheet metal fabrication offers numerous advantages that make it essential for diverse industries:

- High Precision and Consistency: Achieves tight tolerances and complex designs consistently across large production runs.

- Cost-Effectiveness: Particularly efficient for high-volume projects due to streamlined processes like stamping and punching.

- Durability: Metal parts are inherently strong, with options to enhance through various finishing processes.

- Versatility: Suitable for a wide range of applications, from electronics to heavy machinery.

- Customization: Easily tailored to specific requirements, allowing for a broad selection of materials and finishes.

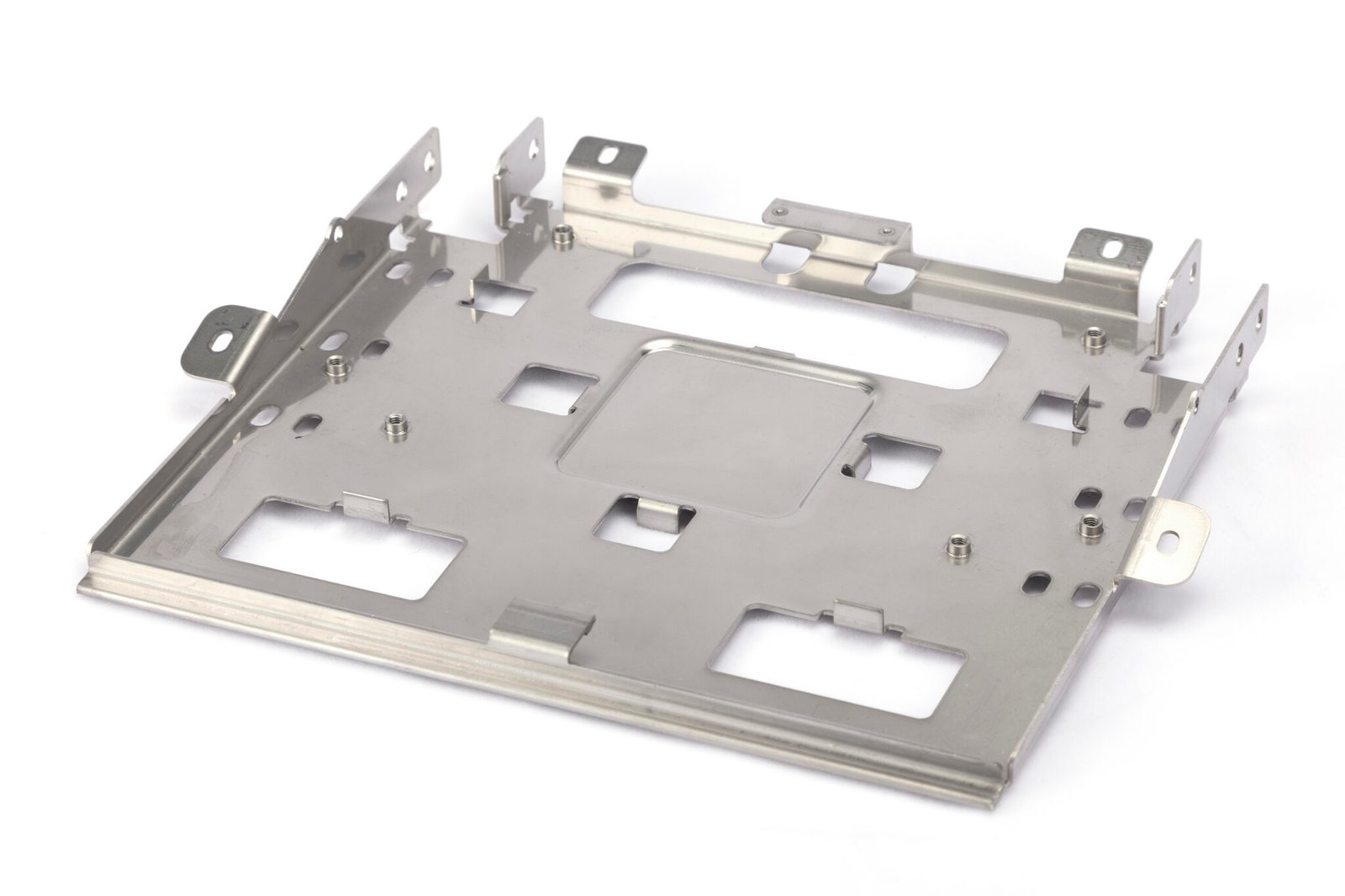

Applications of Sheet Metal Fabrication

Sheet metal fabrication enables the creation of a diverse range of parts and components, each tailored to meet specific functional and aesthetic needs:

- Enclosures and Casings: Protects machinery and electronics, offering structural integrity and heat resistance.

- Brackets and Mounts: Provides support and secure mounting solutions for various applications.

- Panels and Chassis: Forms the external and internal frameworks for vehicles, electronics, and machinery.

- Ductwork and Ventilation Systems: Essential for HVAC systems, ensuring efficient air flow and temperature control.

- Custom Shelving and Storage: Tailored solutions for organizing and storing items securely in commercial and industrial settings.

- Decorative Elements: Adds aesthetic details to buildings, vehicles, and consumer products.

- Prototypes: Facilitates the rapid development and testing of new designs and innovations.

FAQs

Starting a sheet metal project is straightforward and efficient with RapidDirect. First, prepare a detailed design of your part or component. If you’re unsure about the specifications, our team of experienced engineers is ready to assist you in optimizing your design for fabrication.

Next, upload your design files directly to our online quoting system. Here, you can easily configure part specifications such as material selection, thickness, and finishing options. Once submitted, you will receive a customized quote based on your project’s requirements.

After you approve the quote, we’ll begin the fabrication process. Our advanced machinery and skilled technicians ensure precision and quality. You’ll be updated throughout the process, from manufacturing to the final delivery of your parts.

The lead time for receiving your custom sheet metal parts depends on several factors including the complexity of the parts, the quantity ordered, and the specific fabrication processes required. For simple parts, we can often deliver within as little as 3 days from the time your order is placed and the design is confirmed.

For more complex assemblies or larger volumes, the production time will be extended accordingly. Once you submit your design through our online quoting system, we provide an estimated delivery timeline along with your quote. This estimate takes into account the current workload in our fabrication facilities and the specific requirements of your project.

We strive to minimize turnaround time without compromising on quality, ensuring you receive your parts as quickly as possible while maintaining the highest standards of fabrication.

The cost of sheet metal fabrication varies widely based on several factors including the complexity of the parts, the type of material used, the quantity of parts, and the specific fabrication processes required. For straightforward, simple parts, the cost can be quite competitive, especially when leveraging our efficient production techniques and advanced machinery.

To get a specific cost estimate, we encourage you to use our easy-to-use online quoting system. Here, you can upload your design files, select materials, specify quantities, and choose finishing options. Our system will provide you with a detailed quote reflecting the precise cost of your project.

For larger or more complex orders, costs will adjust based on additional processing and labor required. Our goal is always to offer the best value, combining cost-effectiveness with high-quality results.

At Futai, we support projects of all sizes. We accommodate both small and large production runs, offering our services for everything from a single prototype to mass production. Importantly, we do not enforce a strict minimum order quantity. This flexibility allows customers, whether startups or large corporations, to leverage our sheet metal fabrication services tailored to their specific needs and scales.

Sheet Metal Fabrication Resources

Waterjet Cutting: Techniques, Uses, and Advantages

Comprehensive Guide to Sheet Metal Hemming: Techniques,