Rapid Prototyping Services

Rapid prototyping services with the use of state-of-the-art manufacturing processes,

including sheet metal fabrication, precision casting,CNC machining and 3D printing.

Guarantees fast lead time of high-quality prototypes at minimal cost.

• Various rapid prototyping services.

• Abundant materials & finishes.

• One-stop rapid prototyping services and production solutions.

Superior Rapid Prototyping

Futai rapid prototyping is a product development method that allows the production and iteration of product parts for evaluation and testing. By manufacturing your rapid prototypes with Futai guarantees, you make the best decision regarding your design. We let you test out a full range of materials and finishes, so you can make an informed decision on how to take your project forward. We have an array of rapid prototyping processes for you to choose from.

Why Choose Futai for Rapid Prototyping Services

Our top-quality rapid prototyping service guarantees a fast lead time, ensuring you receive your products and parts within the deadline at minimal tooling cost.

Instant Quotation and Automated DFM Analysis

Thanks to our new and advanced quotation platform , you instantly get your quotation and DFM analysis. The updated machine learning algorithm process tons of information in a short period and gives us all the needed information about your orders.

Consistent High Quality

We use high-quality input materials and maintain a high level of process stability to ensure reproducibility. We strive for continuous improvement to improve our manufacturing of goods, processes, and delivery capability.

Strong Manufacturing Capabilities

To meet your rapid prototyping needs, we provide and support extensive manufacturing capabilities. For low volume CNC machining, injection molding, 3D printing, and other services, our goal is to bring your prototypes or parts to life in best possible way.

Fast Lead Time

We have a state-of-the-art in-house production supply chain and staff strength that helps us meet and exceed your expectations on delivery time and quantity. We ensure that all our deliveries are within schedule.

Established Supply Chain System

Our leading suppliers help us receive materials for consistent production while ensuring every product is at affordable costs.

24/7 Engineering Support

Our team of refined and experienced experts is always available for professional advice and recommendation on your orders, improvements, and preferences.

Our Rapid Prototyping Capabilities

|

Rapid Sheet Metal Fabrication |

|

Take advantage of Futai’s streamlined sheet metal processing to produce metal parts. The combination of advanced equipment and in-house production ensures short lead times and strict quality standards. CNC machining, including both CNC milling and CNC turning, is an excellent choice for rapid prototyping when parts need to be assessed in their final material form. This method allows for prototypes to be made from fully dense stock, providing accurate and durable models. Futai specializes in machining a broad spectrum of metals and plastics, ensuring versatility for your project requirements. Our rapid CNC prototyping services deliver high-quality machined prototype quickly, often in 1 day. This speed, coupled with our cost-effective pricing, allows engineers to order multiple prototypes at once, facilitating quick and thorough product evaluations. Choosing Futai for your CNC prototyping needs means benefiting from our expertise and commitment to precision. We provide various expedite options, ensuring that urgent projects are completed on time. Our market-based pricing model ensures affordability without compromising quality. With Futai, you receive detailed and accurate prototypes that support rapid product development, from initial design to final production. |

|

| Get Instant Quote |

|

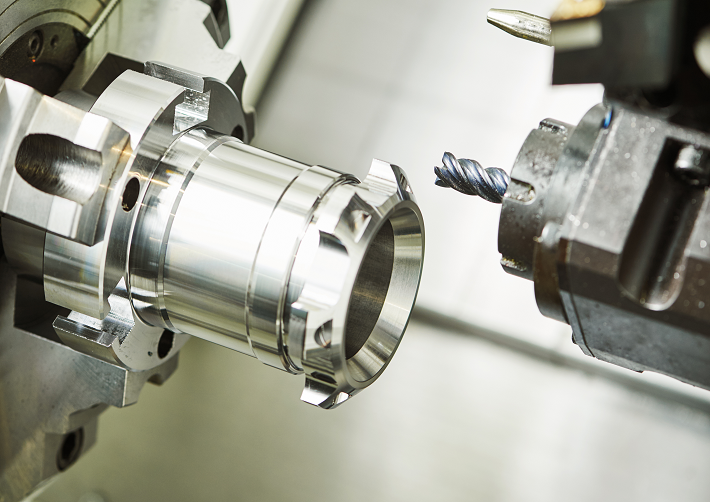

Rapid CNC Machining |

| For rapid prototyping of plastic and metal parts, CNC machining is the ideal production option, as we can create all the prototypes you need with precision detail and complete them within a short lead time. CNC machining, including both CNC milling and CNC turning, is an excellent choice for rapid prototyping when parts need to be assessed in their final material form. This method allows for prototypes to be made from fully dense stock, providing accurate and durable models. Futai specializes in machining a broad spectrum of metals and plastics, ensuring versatility for your project requirements. Our rapid CNC prototyping services deliver high-quality machined prototype quickly, often in 1 day. This speed, coupled with our cost-effective pricing, allows engineers to order multiple prototypes at once, facilitating quick and thorough product evaluations. Choosing Futai for your CNC prototyping needs means benefiting from our expertise and commitment to precision. We provide various expedite options, ensuring that urgent projects are completed on time. Our market-based pricing model ensures affordability without compromising quality. With Futai, you receive detailed and accurate prototypes that support rapid product development, from initial design to final production. |

|

| Get Instant Quote |

|

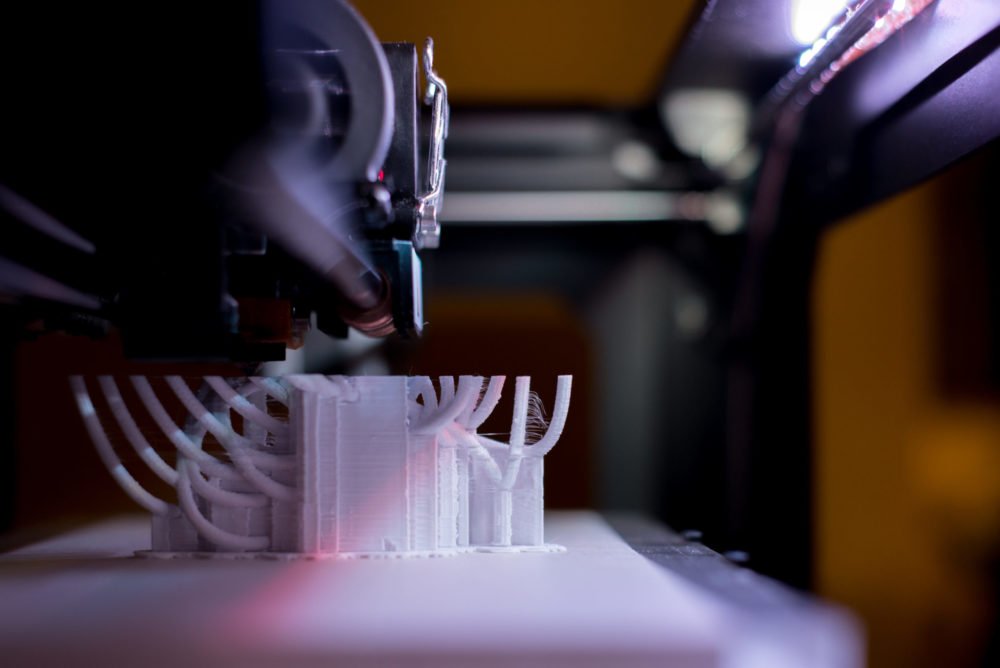

Rapid 3D Printing |

| Utilizing the latest 3D printing technology, Futai caters to your rapid 3D printing needs, such as SLA, SLS, FDM, and more. With our fast production capabilities and streamlined process, you’re guaranteed to get your custom parts within a few days. 3D printing stands out as the leading method for rapid prototyping due to its speed and cost-effectiveness. This technique enables the quick and economical creation of prototypes, often ready for dispatch within a day at minimal cost. The primary 3D printing methods for rapid prototyping include Selective Laser Sintering (SLS), Stereolithography (SLA), and Fused Deposition Modeling (FDM). SLS is highly versatile, offering a balance of speed, mechanical functionality, detailed resolution, and affordability. SLA provides the finest surface finish and exceptional accuracy, making it perfect for creating clear parts with precise tolerances. FDM is ideal for producing larger parts from a variety of engineered thermoplastics such as ABS, PC, and ULTEM, capable of fabricating items up to 36” in size in a single piece. Choosing Futai for your 3D printing needs ensures you benefit from our expertise and advanced capabilities. We manufacture high-quality 3D printed parts that meet your specific project requirements. With Futai, you receive reliable, precise, and fast prototyping solutions that help accelerate your product development process. |

|

| Get Instant Quote |

Material Options for Rapid Prototyping

We provide quotations for over 100 metals and plastics for your prototyping needs. On our platform, you can also view the different materials and the cost of their machining.

There are different types of metals, each with different physical and chemical properties. These differences make some metals better suited to a particular application than others. The methods for producing metal prototypes include; CNC machining, Casting, 3D printing, and sheet fabrication.

Brass Titanium

Aluminum Copper

Stainless Steel

More Details>>

Types of Rapid Prototype

The rapid prototyping process is far-reaching, encompassing several materials, technologies, and industries. There are four different types of rapid prototypes.

| Concept Model This is one of the simplest types of prototypes. Also called a proof-of-concept prototype, engineers use the concept model to convey the basic idea of the design. Before use, this type of prototype undergoes multiple changes. |

|

Display Prototype Engineers develop this type of prototype to make it look similar to the final product. Most times, functionality is not a factor considered under the display prototype as the focus is mainly on appearance. |

|

Functional Prototype This prototype focuses on functionality and aims to enable engineers and designers to test the product to make modifications if any, for optimal functionality. The prototype developed here should behave the same way as the final product. |

|

Pre-Production Prototype This is the last type of prototype developed before production. There are two major purposes of this type of prototype. First, to validate the process chosen by the manufacturer for mass production, and second, to ensure the manufactured part functions optimally. |

From Rapid Prototyping to Production

Having been in the prototyping and production industry since 2013, we help startups and established brands manufacture prototypes and products that compete favorably in the global market. This is a testament to the quality and precision of our machines and a seasoned team of professionals working tirelessly to ensure your top-quality products get to the market as when due.

At Futai manufacturer, we offer top-notch services that encompass all aspects of manufacturing, from prototyping to production. Our rapid prototyping services include rapid 3d printing services, CNC rapid machining services, precision sheet metal processing services, considering your ideal prototyping material. Our rapid prototyping and production services considerably cut the production cost for you while reducing the time to market. So work with us today for all your prototyping to production needs.

Sheet Metal Box Fabrication for Different Industries

Electronics

Sheet metal box importance in the electronic industry is beyond measure. They are providing several advantages including emission reductions, electrical conductivity, and so on. These boxes are resistant to harsh industrial environments.

Telecom

Futai specializes in sheet metal box fabrication for communication systems. These cabinets have great features, such as being water-resistant, fireproof, NEMA/UL-tested, and mountable on a wall, tower, or pole. Other models are free-standing.

Aerospace

Boxes for aerospace applications come with a range of material selections. We treat titanium, aluminum, carbon steel, or stainless steel. The dimensions of the pieces are precise and long-lasting. Designed to meet the industry’s stringent requirements.

Energy

Fabricated metal boxes can be utilized to build energy production systems. They are lowering production costs while improving quality and consistency. Futai uses copper, steel, and other materials to build containers for the social energy industry.

Automotive

Futai produces high-quality metal boxes that can withstand the rigors of the semiconductor industry. These enclosures can be used to shield electronics from wear and tear in automobiles. Futai can make large production of boxes for your business.

Explore Related Resources

From prototypes to on-demand production parts, get an instant quote for your metal or plastic projects with our online CNC