For successful steel sheet metal fabrication – choose the right alloy and suitable technique.

This guide will help you choose suitable steel alloys and recommend various fabrication techniques. At the end of it, you will find valuable resources too.

Let’s dive right in:

Steel Types in Steel Sheet Metal Fabrication

Before choosing any steel material for sheet metal fabrication, you should know the various alloy properties.

Remember, every alloy has unique properties making them suitable for specific fabrication technique such as:

- Laser cutting

- Plasma cutting

- Bending

- Drilling, or

- Milling

Alloy Steel

Formation of alloy steel is by combining carbon steel with additional components usually metals and non-metals. The alloying constituents change certain chemical and physical characteristics of these alloy steels.

The alloying element influences the mechanical abilities such as high strength to withstand forging and weldability during fabrication.

Types of Alloy Steel

There are two types of alloy steel defined by the alloy’s constituent element’s weight:

i. High-Alloy Steel: Contains alloying elements in excess of 8% and costs much higher than low-alloy steel finding use in vehicles and industrial machinery.

ii. Low-Alloy Steel: Contains alloying elements less the 8% percent exhibiting various strengths and uses defined by the alloying elements.

Alloying Elements

In creating different alloy steel grades, you combine carbon steel with alloying elements to punctuate a variety of properties. The following are some of the elements employed and their results:

- Aluminium: Expels oxygen, phosphorus, and sulfur from steel increasing surface hardness a property suitable for forging processes.

- Tungsten: Enhances grain structure, boosts strength and hardness and offers better heat resistance to support fabrication using force and heat.

- Chromium: Boosts alloy steel’s toughness, hardness, and wear resistance to sustain forming techniques like cold forging.

- Cobalt: Improves hot hardness, increases toughness and wear resistance allowing hot working operations.

- Vanadium: Can boost toughness, strength, shock and corrosion resistance useful in fabrication operations such as blanking and bending.

- Copper: Improves hardness and corrosion resistance increasing the alloy steel’s machinability.

- Manganese: Increases surface hardness, ductility, wear resistance, strength at high temperatures and strain resistance improving hot working and weldability.

- Molybdenum: Strengthens alloy steel and enhances resilience to heat and stress for fabrication processes requiring heat treatment.

- Nickel: Enhances corrosion resistance, hardness and strength suitable during processes such as cold forging.

- Silicon: Improves the alloy’s magnetic properties and strength requisite for fabrication techniques involving force application.

Applications of Alloy Steel

Some of the most common steel sheet fabricated parts applications include:

i. Alloy steel sheets find use in the production of corrosion-resistant containers, silverware, heating elements and pots and pans.

ii. The production of aviation parts, structural sections, girders and ship propellers.

iii. Providing structural parts, mining equipment, automobile manufacture and railroad cars.

Carbon Steel

Carbon steel contains higher carbon content than stainless steel offering more durability and lowering the melting point.

Carbon steel constitutes the majority of all steel sheet metal fabrication activities.

Types of Carbon Steel

The carbon content in carbon steel determines its classification as follows:

i. Low-Carbon Steel: Has a carbon content of less than 0.25% finding the most common use of the carbon steel types. However, its brittle property and susceptibility to deformation under tension make it unsuitable to harsh fabrication techniques such as punching.

Properties

- More brittle and ductile.

- Easier to weld during fabrication.

- Less expensive to machine.

- Deforms under tension.

Application

- Making steel plates

- Fabricating body panels for vehicles.

- Manufacturing food cans

Medium-Carbon Steel: Has manganese contents ranging from 0.6% to 1.65% and carbon contents between 0.25% and 0.6%. The improved mechanical qualities allow use of cold working techniques such as bending and shearing during fabrication.

Properties

- Heat treatment enhances mechanical qualities.

- Stronger than low-carbon steel.

- Less ductile and robust than low-carbon steel.

- High resistance to wear and enhanced toughness.

Application

- Making railway tracks and wheels.

- Production of machinery parts such as gears.

i. High Carbon Steel: Contains 0.3-0.9% manganese and between 0.6-1.25% carbon making it the strongest and most durable carbon steel type. High-carbon steel is highly machinable by employing methods such as shearing, bending and rolling.

Properties

- High wear resistance

- Low ductility

- Constant hardening and tempering process

- Break easily under tension

Applications

- Fabrication of bridge components

- Structures and parts in oil and gas industries

- Shipbuilding

Stainless Steel

Stainless steel contains iron and a minimum of 11% chromium offering the highest level of corrosion resistance. You can achieve additional qualities by adding elements such as molybdenum, carbon or nickel.

Other properties of stainless steel are:

- Aesthetically pleasing

- Minimal cost throughout the course of use

- Recyclable and long-lasting

- Resistant to both high and low temperatures

- Simple to clean and maintain

- Stainless steel is easy to fabricate

- Strong and long-lasting

Application

- Production of cookware and cutlery

- Making medical instruments

- Part production in automobiles

- Construction materials in large developments

- Industrial equipment

- Storage containers and tankers for chemicals and food items

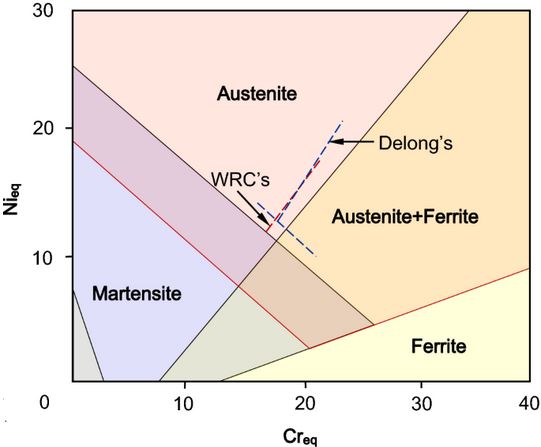

Types of Stainless Steel

Classification of stainless steel is according to the material’s crystalline structure as follows:

Austenitic

Consists the largest group of stainless steel created by alloying steel with nickel, manganese, and nitrogen. The resulting microstructure retains its properties at all temperatures and thus unaffected by heat treatment.

Consequently, austenitic stainless steel exhibits no change under heat treatment during hot working fabrication such as non-shear cutting and welding.

Ferritic

Have a ferrite microstructure similar to carbon steel with little to no nickel and chromium content ranging from 10.5% to 27%. Chromium makes the material temperature resistant supporting hot working activities while adding niobium, titanium, and zirconium improves weldability.

Uses

- Home appliances such as washing machines

- Industrial equipment like boilers

- Exhaust pipes for automobiles

- Uses in architecture and construction

- Elements in construction, including roofing, chimney ducts and slate hooks.

- Solid oxide fuel cells power plates.

Martensitic

Martensitic stainless steels are extremely strong and hard though without the same level of corrosion resistance as austenitic or ferritic types.

They are also magnetic containing about 13% chromium with capability of improving mechanical properties through heat treatment. As such, you can apply tough fabrication methods including cold and hot forging processes such as hammering.

Uses

- Creep-resistant steels

- Engineering and tool steels

- Turbine blades

Duplex

The microstructure of a duplex stainless steel mirrors that of austenite and ferrite usually in a 50:50 configuration. They have a higher chromium content between 19-32%, molybdenum up to 5% and low nickel content.

They offer better yield strength at nearly double austenitic stainless steel and improved chloride stress corrosion cracking resistance. Steel sheets of this type can support various fabrication techniques employing force application such as blanking and rolling.

Uses

- Paper and pulp industry

- Corrosion-resistant containers in oil and gas industry

- Building and construction materials such as bridge plates

- Shipbuilding

Applications of Steel Sheet Metal Fabricated Parts

Steel sheet metal fabricated parts finds use in the following sectors:

i. Construction: Stainless steel is light, strong, durable, low maintenance and affordable relative to other construction materials.

ii. Mining: Steel sheet fabrication allows machinery and tool manufacture such as shovels, trucks, and loading equipment.

iii. Energy Industry: Steel parts find use in electric power turbines, wells for fossil fuels, electromagnetic shields, transmission towers, and solar panels.

Limitations in Fabrication of Steel Sheets

A summary of steel sheet metal fabrication drawbacks is as follows:

- While steel has a long lifespan, it can succumb to oxidation induced corrosion over time requiring maintenance.

- Extended exposure to the elements makes steel materials susceptible to buckling and collapsing.

Futai Manufacturer Steel Sheet Metal Fabrication

At Futai, we design and fabricate a range of steel sheet material parts depending on your specific needs. Our engineers and technicians will help you in design process.

Among the key services we offer include:

- Steel part design

- Laser cutting steel sheet

- Stamping steel sheet parts

- Welding steel sheet metal

- Bending steel sheet metal

- Applying surface finishing steel sheet parts

When it comes to steel sheet metal fabrication, Futai guarantees precise and quality parts at affordable prices.

Conclusion

With the knowledge on properties of steel, you can easily choose suitable sheet metal fabrication method. Additionally, you will match sheet metal part to suit specific application requirements.

For all your steel sheet metal fabrication needs, contact us now.

Alright, crew, saw a banner for da88banner. Looks interesting, might check it out later. Let me know if you all have any intel on it!

NineCasinoApp, my new go-to! The interface is slick, and I’ve already had some decent luck. Definitely worth checking out if you’re looking for a fresh spot to play. Give ninecasinoapp a try!

Just tried out F8betlgoptimusl9 and it’s pretty decent. Easy to navigate and the bonuses are a nice touch. Take a look and see if its your cup of tea. f8betlgoptimusl9

https://www.be2222ph.org I am thanksful for this post!

nustaronline https://www.umnustaronline.org

okebet4 https://www.okebet4u.com

jl10 casino https://www.jl10-casino.net

gkbet https://www.gkbeth.org

phtaya10 https://www.phtaya10y.com

okbet15 https://www.okbet15.org

phtaya06 https://www.phtaya06y.com

philbet https://www.philbetts.net

2222ph https://www.be2222ph.org

jilibet004 https://www.jilibet004.org

peso99 https://www.repeso99.net

nustar online https://www.etnustar-online.com

pin77 online https://www.pin77-online.com

jiliokcc https://www.jiliokccw.com

phtaya11 https://www.phtaya11y.com

phwin25 https://www.phwin25g.net

jl16login https://www.adjl16login.net

a45com https://www.a45com.org

phtaya01 https://www.phtaya01.org

98jili https://www.98jilig.com

pagcor https://www.ngpagcor.net

ph789 login https://www.ph789-login.com

phtaya 63 https://www.phtaya-63.org

93jili https://www.la93jili.net

peryaplus https://www.rsperyaplus.net

9apisologin https://www.it9apisologin.com

tayabet https://www.yetayabet.net

91phcom https://www.91phcom.net

77jili https://www.77jilig.net

jililuck 22 https://www.jililuck-22.com

bet777app https://www.bet777appv.org

jilivip https://www.jilivipu.net

playpal77 https://www.playpal77sy.org

phl789 https://www.nphl789.net

vipjili https://www.vipjiliji.com

777phl casino https://www.777phl.org

slotphlogin https://www.exslotphlogin.net

pin77 app https://www.pin77.tech

okebet168 https://www.okebet168u.org

abjili https://www.babjili.com